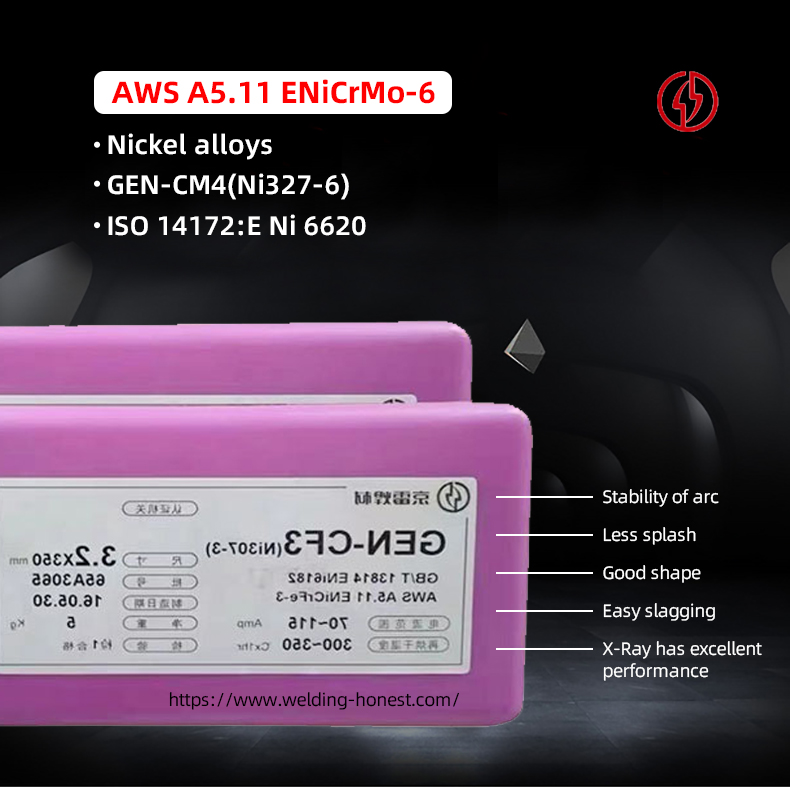

Nikkellegeringen Hânlieding elektrode ENiCrMo-6 weld fabrication jointing

GEMISCHE KOMPONET:

| ALLOY (wt%) | C | Mn | Si | Cr | Ni | Fe | W | Nb+Ta | P | S | |

| GB / T REGELS | 0.10 | 2.0-4.0 | 1.00 | 12.0-17.0 | ≥55 | 10.00 | 1.0-2.0 | 0,5-2,0 | 0.02 | 0.015 | |

| AWS REGELS | 0.10 | 2.0-4.0 | 1.00 | 12.0-17.0 | ≥55 | 10.00 | 1.0-2.0 | 0,5-2,0 | 0.03 | 0.02 | |

| EXEMPEL WAARDE | 0.042 | 2.91 | 0.44 | 13.3 | 70,6 | 4.15 | 1.45 | 1.350 | 0.008 | 0.003 | |

MEGANISCHE EIENDOM:

| BESIT | YIELD STRENGT (MPa) | EXTENSION STRENGTH (MPa) | IMAPACT WAARDE J/℃ | ELONGATION(%) | ||||

| GB / T REGELS | 350 | 620 | - | 32 | ||||

| AWS REGELS | - | 620 | - | 20 | ||||

| EXEMPEL WAARDE | 450 | 720 | 80/-196 | 40 | ||||

Oanrikkemandearre weldingparameters:

| DIAMETER SPESIFIKASJES (mm) | 2,6*300 | 3,2*350 | 4,0*350 | ||||||

| ELEKTRISITEIT (Amp) | H/W | 65-115 | 80-140 | 120-180 | |||||

| O/W | 60-105 | 70-130 | 110-170 | ||||||

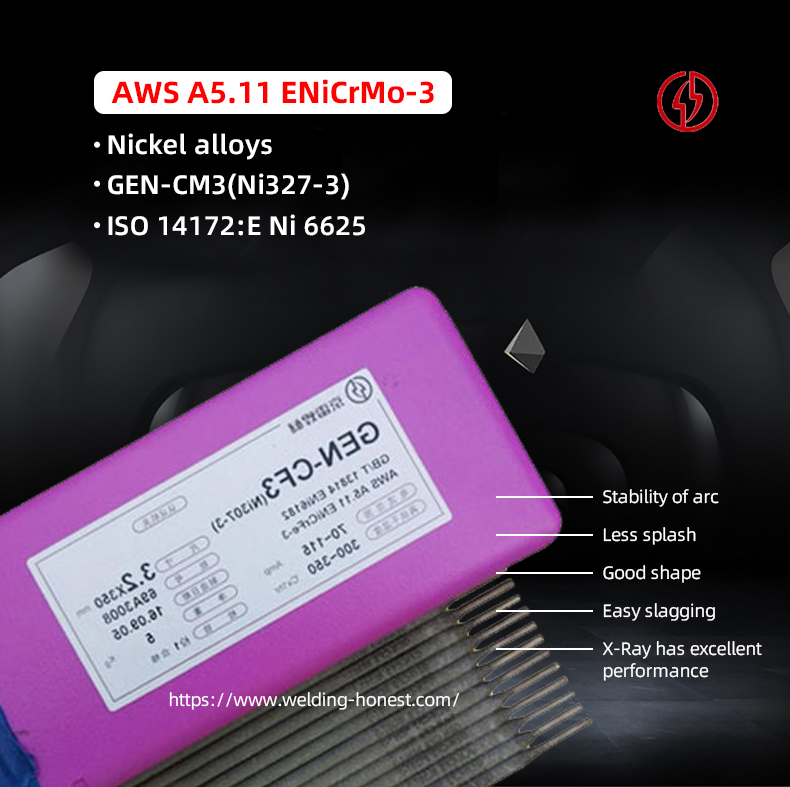

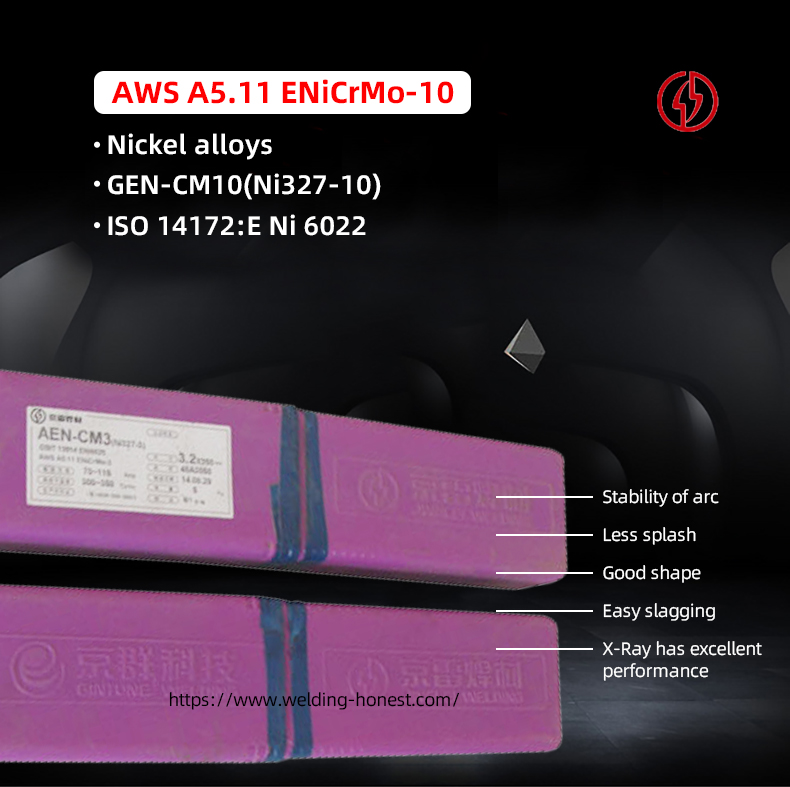

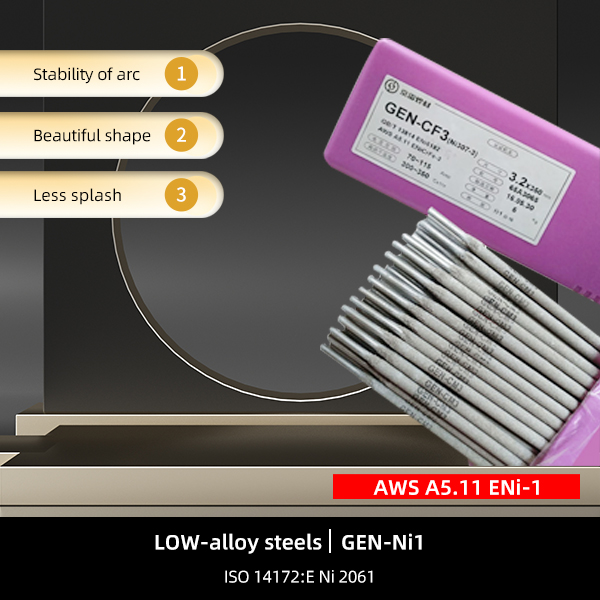

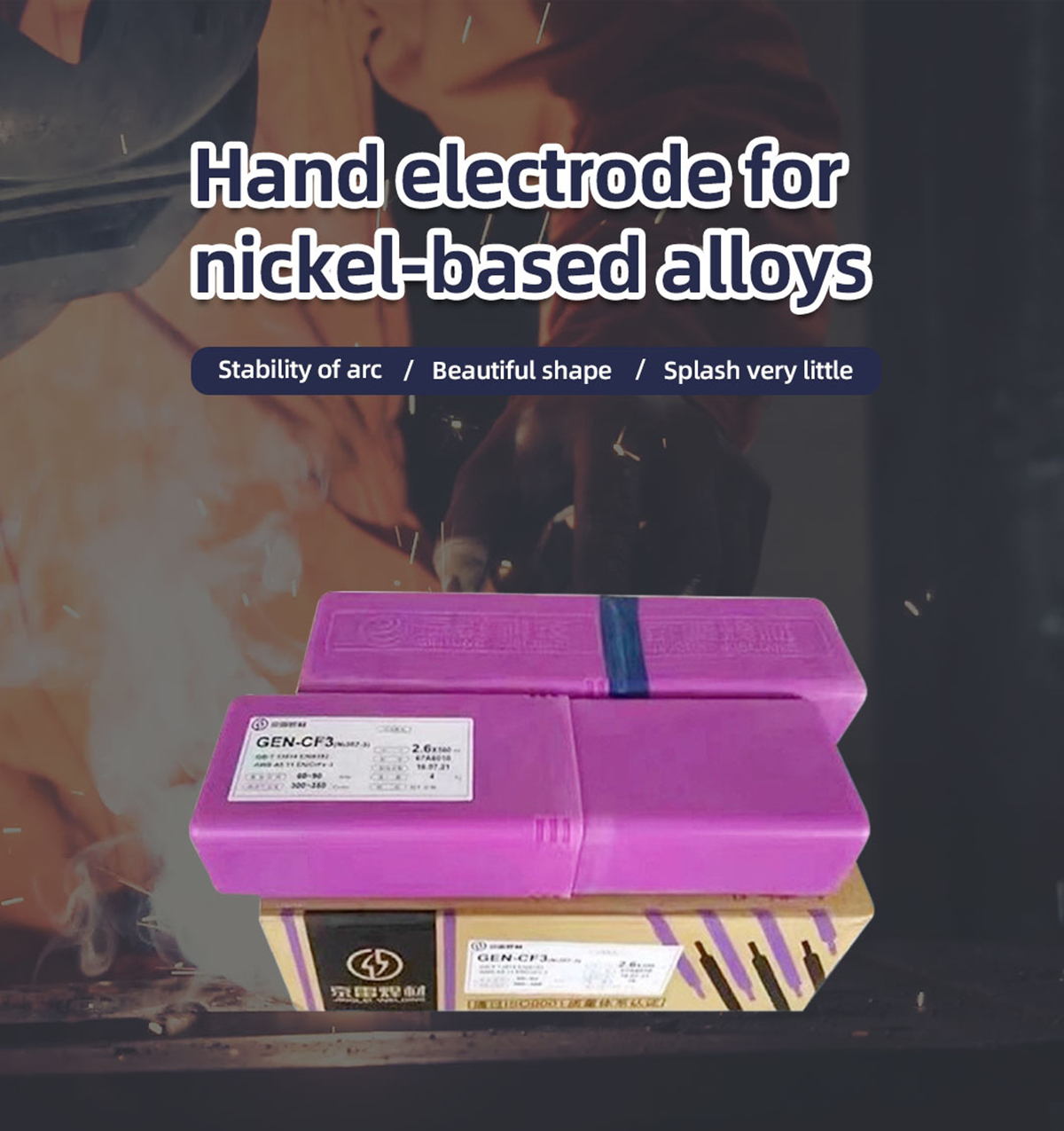

Lege wetterstof type hân elektrodes, nominale gearstalling (gewicht prosint) is 65Ni-14.5Cr-7Fe-7Mo-1.5W-1.5Nb + Ta, nikkel-chrome-molybdeen alloy elektrodes.

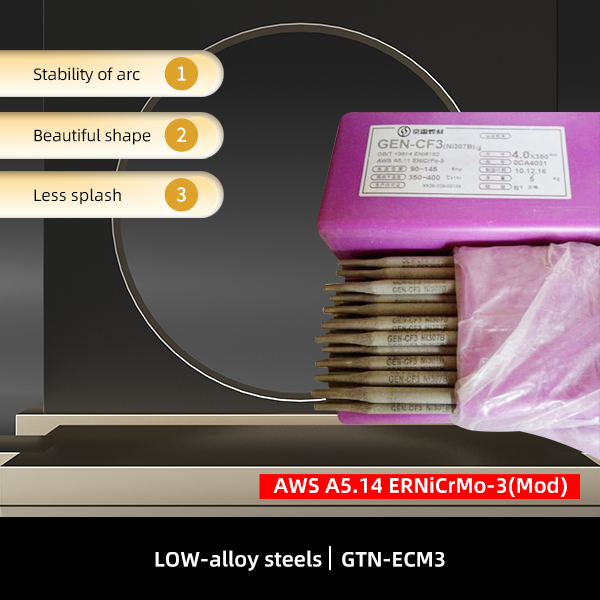

Stabile bôge, prachtige foarming, lytse plons, maklike slagferwidering, goede porositeit ferset, de meganyske eigenskippen fan smelte metaal is stabyl.

Lege temperatuer impact taaiens is poerbêst by -196 ℃, en hat in termyske útwreiding koeffizient fergelykber mei 9% Ni stiel.

-

Shandong Zibo Haiyi 8 sets 3000m³ propylene sferyske tank

-

JU2000E jack-up drilling rig

-

85000 m3 Very Large Ethane Ethylene Carrier (VLEC)

GEMISCHE KOMPONET:

| ALLOY (wt%) | C | Mn | Si | Cr | Ni | Fe | W | Nb+Ta | P | S | |

| GB / T REGELS | 0.10 | 2.0-4.0 | 1.00 | 12.0-17.0 | ≥55 | 10.00 | 1.0-2.0 | 0,5-2,0 | 0.02 | 0.015 | |

| AWS REGELS | 0.10 | 2.0-4.0 | 1.00 | 12.0-17.0 | ≥55 | 10.00 | 1.0-2.0 | 0,5-2,0 | 0.03 | 0.02 | |

| EXEMPEL WAARDE | 0.042 | 2.91 | 0.44 | 13.3 | 70,6 | 4.15 | 1.45 | 1.350 | 0.008 | 0.003 | |

MEGANISCHE EIENDOM:

| BESIT | YIELD STRENGT (MPa) | EXTENSION STRENGTH (MPa) | IMAPACT WAARDE J/℃ | ELONGATION(%) | ||||

| GB / T REGELS | 350 | 620 | - | 32 | ||||

| AWS REGELS | - | 620 | - | 20 | ||||

| EXEMPEL WAARDE | 450 | 720 | 80/-196 | 40 | ||||

Oanrikkemandearre weldingparameters:

| DIAMETER SPESIFIKASJES (mm) | 2,6*300 | 3,2*350 | 4,0*350 | ||||||

| ELEKTRISITEIT (Amp) | H/W | 65-115 | 80-140 | 120-180 | |||||

| O/W | 60-105 | 70-130 | 110-170 | ||||||

Skriuw jo berjocht hjir en stjoer it nei ús