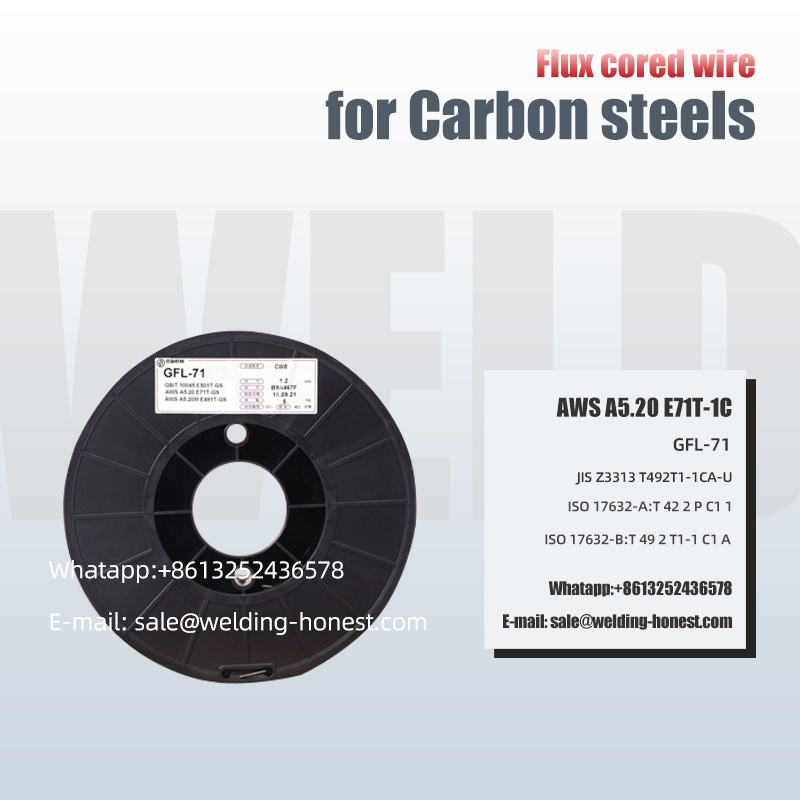

High Carbon stielen E71T-1C Flux coreed wire welding stuff

Applikaasje & Standert

1. Geskikt foar skip, brêge, bou, offshore platfoarm, pipeline, stielstruktuer welding.

2. De standert dy't wy moete: GB/T10045 T 49 2 T1-1 C1 A , AWS A5.20 E71T-1C & A5.20M E491T-1C, ISO17632-A: T42 2 P C1 1, ISO 17632-T49 2 T1 -A C1 A

JIS Z3313 T49T1-1CA-U

Features

1.De bôge is sêft en stabyl, minder spatten, prachtige foarmjen, goede desagging, minder roet, en hat poerbêste weldingprosesprestaasjes. Excellent lege temperatuer ynfloed prestaasjes.

Bedriuw & Fabryk

Produkt gearstalling en meganyske eigenskippen yntroduksje

GEMISCHE KOMPONET:

| ALLOY (wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | V |

| GB / T REGELS | 0.18 | 2.00 | 0,90 | 0.20 | 0,50 | 0.30 | 0.030 | 0.030 | 0.08 |

| AWS REGELS | 0.12 | 1.75 | 0,90 | 0.20 | 0,50 | 0.30 | 0.030 | 0.030 | 0.08 |

| EXEMPEL WAARDE | 0.040 | 1.300 | 0.40 | 0.02 | 0.01 | 0.01 | 0.011 | 0.005 | 0.01 |

MEGANISCHE EIENDOM:

| BESIT | YIELD STRENGT (MPa) | EXTENSION STRENGTH (MPa) | HEATTREAMENT℃xh | IMAPACT WAARDE J/℃ | ELONGATION(%) | ||||

| GB / T REGELS | 390 | 490-670 | AW | 27/-20 | 18 | ||||

| AWS REGELS | 390 | 490-670 | AW | 27/-20 | 22 | ||||

| EXEMPEL WAARDE | 480 | 550 | AW | 125/-20 | 28 | ||||

Oanrikkemandearre weldingparameters:

| DIAMETER SPESIFIKASJES (mm) | 1.2 | 1.4 | 1.6 | ||||

| VOLT | 23-32 | 24-36 | 25-40 | ||||

| AMP | 150-300 | 170-360 | 200-400 | ||||

| MM | 15-20 | 15-20 | 18-25 | ||||

| L/MIN | 15-25 | 15-25 | 15-25 |

NOAT:

H / W: horizontale posysje welding. O / W: over-head posysje welding

CERTIFICATION AUTORITY:ABS/BV/CCS/DNV/GL/LR/NK/CE/JIS

TYPISKE GEVALLEN

Sertifikaten

GEMISCHE KOMPONET:

| ALLOY (wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | V |

| GB / T REGELS | 0.18 | 2.00 | 0,90 | 0.20 | 0,50 | 0.30 | 0.030 | 0.030 | 0.08 |

| AWS REGELS | 0.12 | 1.75 | 0,90 | 0.20 | 0,50 | 0.30 | 0.030 | 0.030 | 0.08 |

| EXEMPEL WAARDE | 0.040 | 1.300 | 0.40 | 0.02 | 0.01 | 0.01 | 0.011 | 0.005 | 0.01 |

MEGANISCHE EIENDOM:

| BESIT | YIELD STRENGT (MPa) | EXTENSION STRENGTH (MPa) | HEATTREAMENT℃xh | IMAPACT WAARDE J/℃ | ELONGATION(%) | ||||

| GB / T REGELS | 390 | 490-670 | AW | 27/-20 | 18 | ||||

| AWS REGELS | 390 | 490-670 | AW | 27/-20 | 22 | ||||

| EXEMPEL WAARDE | 480 | 550 | AW | 125/-20 | 28 | ||||

Oanrikkemandearre weldingparameters:

| DIAMETER SPESIFIKASJES (mm) | 1.2 | 1.4 | 1.6 | ||||

| VOLT | 23-32 | 24-36 | 25-40 | ||||

| AMP | 150-300 | 170-360 | 200-400 | ||||

| MM | 15-20 | 15-20 | 18-25 | ||||

| L/MIN | 15-25 | 15-25 | 15-25 |

NOAT:

H / W: horizontale posysje welding. O / W: over-head posysje welding

CERTIFICATION AUTORITY:ABS/BV/CCS/DNV/GL/LR/NK/CE/JIS